| Railroad-Highway Grade Crossing Handbook - Revised Second Edition August 2007 | |

| Section 5: Selection of Alternatives | Table of Contents | Previous | Next |

V

Selection of Alternatives

This chapter discusses methods for selecting alternatives and the economic analysis techniques that may be utilized. Although procedures are provided for developing benefit-cost analyses of alternative treatments, more recent trends place emphasis on risk avoidance and best practices. As a result, benefit-cost studies may only be useful for evaluating alternatives that involve a major investment. Benefit-cost analysis requirements are contained in 23 CFR 924. In addition, the Rail-Highway Crossing Resource Allocation Procedure is presented and other low-cost solutions are discussed.

A. Technical Working Group Guidance on Traffic Control Devices—Selection Criteria and Procedure

The Technical Working Group (TWG) established by the U.S. Department of Transportation (U.S. DOT) is led by representatives from the Federal Highway Administration (FHWA), Federal Railroad Administration (FRA), Federal Transit Administration, and National Highway Traffic Safety Administration. This cooperation among the various representatives of TWG represents a landmark effort to enhance communication among highway agencies, railroad companies and authorities, and governmental agencies involved in developing and implementing policies, rules, and regulations.

The TWG document is intended to provide guidance to assist engineers in the selection of traffic control devices or other measures at highway-rail grade crossings.118 It is not to be interpreted as policy or standards and is not mandatory. Any requirements that may be noted in the report are taken from the Manual on Uniform Traffic Control Devices (MUTCD) or another document identified by footnotes. A number of measures are included that may not have been supported by quantitative research but are being used by states and local agencies. These are included to inform practitioners of the array of tools being used or explored.

The introductory materials developed by the U.S. DOT TWG present an excellent perspective on the functioning of a highway-rail grade crossing. TWG notes that a highway-rail grade crossing differs from a highway-highway intersection in that the train always has the right of way. From this perspective, TWG indicates that the process for deciding what type of highway traffic control device is to be installed or even allowing that a highway-rail grade crossing should exist is essentially a two-step process, requiring consideration of what information the vehicle driver needs to be able to cross safely and whether the resulting driver response to a traffic control device is “compatible” with the intended system operating characteristics of the highway and railroad facility.

The TWG guidance outlines the technical considerations for satisfying motorist needs, including the role of stopping sight distance, approach (corner) sight distance, and clearing sight distance, and integrates this with highway system needs based upon the type and classification of the roadway as well as the allowable track speeds by class of track for the railway system. This handbook describes tools and analytical methodologies as well as treatments and criteria from a variety of sources for selecting treatments; the TWG document and its introduction should be consulted by persons involved with studies of grade crossing safety issues and improvements.

These treatments are provided for consideration at every public highway-rail grade crossing. Specific MUTCD signs and treatments are included for easy reference.

TECHNICAL WORKING GROUP GUIDANCE 1. Minimum Devices All highway-rail grade crossings of railroads and public streets or highways should be equipped with approved passive devices. For street-running railroads/transit systems, refer to MUTCD Parts 8 and 10. 2. Minimum Widths All highway-rail grade crossing surfaces should be a minimum of 1 foot beyond the edge of the roadway shoulder, measured perpendicular to the roadway centerline, and should provide for any existing pedestrian facilities. 3. Passive—Minimum Traffic Control Applications a. A circular railroad advance warning (W10-1) sign shall be used on each roadway in advance of every highway-rail grade crossing except as described in MUTCD. b. An emergency phone number should be posted at the crossing, including the U.S. DOT highway-rail grade crossing identification number, highway or street name or number, railroad milepost, and other pertinent information. c. Where the roadway approaches to the crossing are paved, pavement markings are to be installed as described in MUTCD, subject to engineering evaluation. d. Where applicable, the “Tracks Out Of Service” sign should be placed to notify drivers that track use has been discontinued. e. One reflectorized crossbuck sign shall be used on each roadway approach to a highway-rail grade crossing.

f. Supplemental passive traffic control applications (subject to engineering evaluation):

Table 42. Guidelines for Active Devices

Note: 1 mile per hour (mph) = 1.61 kilometers per hour (km/hr.) * Refer to the 2003 edition of MUTCD, Part 10, transit and light-rail trains in medians of city streets. ** Except 35 mph (56 km/hr.) for transit and light-rail trains. Source: Guidance on Traffic Control Devices at Highway-Rail Grade Crossings. Washington, DC: Federal Highway Administration, Highway/Rail Grade Crossing Technical Working Group, November 2002. 4. Active If active devices are selected, the following devices should be considered:

5. Closure Highway-rail grade crossings should be considered for closure and vacated across the railroad right of way whenever one or more of the following apply:

6. Grade Separation

Table 43. LRT Grade Separation

Source: Light Rail Transit Grade Separation Guidelines, An Informational Report. Washington, DC: Institute of Transportation Engineers, Technical Committee 6A-42, March 1992. 7. New Crossings

8. Traffic Control Device Selection Procedure Step 1—Minimum highway-rail grade crossing criteria (see report for full description):

Step 2—Evaluate highway traffic flow characteristics:

Step 3—Possible revision to the highway-rail grade crossing:

Step 4—Interim measures and/or documentation:

1 Guidance on Traffic Control Devices at Highway-Rail Grade Crossings. Washington, DC: Federal Highway Administration (FHWA), Highway/Rail Grade Crossing Technical Working Group, November 2002. 2 Ibid. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

B. Guidance on STOP and YIELD Signs

The National Committee on Uniform Traffic Control Devices (NCUTCD) has recommended revising MUTCD to mandate the use of YIELD signs at passive crossings except when STOP signs are determined appropriate by engineering study or engineering judgment. NCUTCD’s recommendation is based on National Cooperative Highway Research Program Report 470, Traffic-Control Devices for Passive Railroad-Highway Grade Crossings. FHWA will consider proposing changes regarding the use of YIELD or STOP signs at passive grade crossings in the next edition of MUTCD. FHWA issued a guidance memo on March 17, 2006, which provided installation details and further instructs FHWA field personnel to work with local authorities to implement the use of YIELD signs (or STOP signs, where appropriate) at passive grade crossings.

It is recommended that YIELD signs be considered the default choice for traffic control at a passive crossing unless an engineering study or judgment determines that a STOP sign is appropriate. A STOP sign establishes a legal requirement for each and every vehicle to come to a full stop. Indiscriminate use of the STOP sign at all or many passive grade crossings can cause poor compliance, increasing the risk of collisions associated with a high non-compliance rate.

Therefore, the use of STOP signs at passive crossings should be limited to unusual conditions, where requiring all vehicles to make a full stop is deemed essential by engineering study or judgment. The engineering study or engineering judgment should consider:

• The line of sight from an approaching highway vehicle to an approaching train.

• Characteristics of the highway, such as the functional classification, geometric conditions, and traffic volumes and speed.

• Characteristics of the railroad, including but not limited to frequency, type, speed of trains, and number of tracks.

• Crossing crash history.

• Need for active control devices.

It should be noted that certain commercial motor vehicles and school buses are required to stop at all highway-rail grade crossings, in accordance with 49 CFR 392.10, even if a YIELD sign or just a crossbuck sign is posted.

C. Canadian Research on Cost Effectiveness

Canadian research includes evaluation of the tradeoffs between benefits and costs and takes into consideration the human factors in relation to effectiveness, as shown in Table 44.

D. Economic Analysis Procedures

An economic analysis may be performed to determine the possible alternative improvements that could be made at a highway-rail grade crossing. These procedures involve estimates of expected project costs and safety and operational benefits for each alternative. Much of the following discussion is adapted from the methodology presented in the Highway Safety Improvement Program User’s Manual.

Initially, information on the following elements must be established, using the best available facts and estimates:

• Collision costs.

• Interest rates.

• Service life.

• Initial improvement costs.

• Maintenance costs.

• Salvage value.

• Traffic growth rates.

Other considerations include the effectiveness of the improvement in reducing collisions and the effects on travel, such as reducing delays.

Cost information is not always readily available. Therefore, some states are reluctant to impute a dollar cost to human life or personal injury. Considerable care must be used in establishing values for these costs.

The selection of collision cost values is of major importance in economic analyses. The two most common sources of collision costs are:

• National Safety Council (NSC).

• National Highway Traffic Safety Administration (NHTSA).

NSC costs include wage losses, medical expenses, insurance administrative costs, and property damage. NHTSA includes the calculable costs associated with each fatality and injury plus the cost to society, such as consumption losses of individuals and society at large caused by losses in production and the inability to produce. Many states have developed their own values, which reflect their situation and philosophy. Whichever is selected, the values ought to be consistent with those used for other safety improvement programs.

Table 44. Countermeasure Type, Effectiveness, and Cost

Countermeasure |

Effectiveness |

Cost |

STOP signs at passive crossings |

Unknown |

$1,200 to $2,000 |

Intersection lighting |

52-percent reduction in nighttime collisions over no lighting |

Unknown |

Flashing lights |

64-percent reduction in collisions over crossbucks alone 84-percent reduction in injuries over crossbucks 83-percent reduction in deaths over crossbucks |

$20,000 to $30,000 in 1988 |

Lights and gates (two) with flashing lights |

88-percent reduction in collisions over crossbucks alone 93-percent reduction in injuries over crossbucks 100-percent reduction in deaths over crossbucks 44-percent reduction in collisions over flashing lights alone |

$150,000 |

Median barriers |

80-percent reduction in violations over two-gate system |

$10,000 |

Long arm gates (three-quarters of roadway covered) |

67 to 84–percent reduction in violations over two-gate system |

Unknown |

Four-quadrant gate system |

82-percent reduction in violations over two-gate system |

$125,000 from standard gates $250,000 from passive crossing |

Four-quadrant gate system with median barriers |

92-percent reduction in violations over two-gate system |

$135,000 |

Crossing closure |

100-percent reduction in violations, collisions, injuries, deaths |

$15,000 |

Photo/video enforcement |

34 to 94–percent reduction in violations |

$40,000 to $70,000 per installation |

In-vehicle crossing safety advisory warning systems |

Unknown |

$5,000 to $10,000 per crossing plus $50 to $250 for a receiver |

Note: The effectiveness of a countermeasure is expressed as a function of the percentage reduction in collisions and other violations over some previous treatment. Costs are expressed in U.S. dollars (approximate year 2000 amounts).1

Source: Guidance on Traffic Control Devices at Highway-Rail Grade Crossings. Washington, DC: Federal Highway Administration, Highway/Rail Grade Crossing Technical Working Group, November 2002.

1 “A Human Factors Analysis of Highway-Railway Grade Crossing Accidents In Canada.” Transportation Development Centre, Transport Canada, September 2002 (www.tc.gc.ca/tdc/summary/14000/14003.htm).

An appropriate interest rate is needed for most of the procedures considered. The selection of an inappropriate interest rate could result in unsuitable project costs and benefits and, thus, selection of an ineffective solution. Periods of rapid inflation and fluctuation of interest rates make the identification of an appropriate rate somewhat difficult. The standard rates used by the highway department should be selected.

The Highway Safety Improvement Program User’s Manual states that the service life of an improvement should be equal to the time period that the improvement can reasonably affect collision rates. Both costs and benefits should be calculated for this time period. Hence, the service life is not necessarily the physical life of the improvement. For highway-rail grade crossings, however, it is a reasonable assumption that the improvement would be equally effective over its entire physical life. Thus, selecting the service life equal to the physical life would be appropriate. In particular, service life of signal equipment is fairly long because signals are visited by a maintainer at least once per month.

The selected service life can have a profound effect on the economic evaluation of improvement alternatives; therefore, it should be selected using the best available information.

Project costs should include initial capital costs and maintenance costs and should be considered life-cycle costs; in other words, all costs are distributed over the service life of the improvement. The installation cost elements include the following:

• Preliminary engineering.

• Labor.

• Material.

• Lease or rental of equipment.

• Miscellaneous costs.

The maintenance costs are all costs associated with keeping the system and components in operating condition. Maintenance costs are discussed in Chapter VII.

The salvage value may be an issue when a highway is upgraded or relocated, a railroad line is abandoned, etc. Salvage value is defined as the dollar value of a project at the end of its service life and, therefore, is dependent on the service life of the project. For crossing signal improvement projects, salvage values are generally very small. Due to the characteristics of crossing signals and control equipment as well as the liability concerns that arise from deploying “secondhand” signals, it is assumed that there is zero salvage value after 10 years.

There are several accepted economic analysis methods, all of which require different inputs, assumptions, calculations, and methods and may yield different results. Several appropriate methods are described here.

1. Cost-Effectiveness Analysis

The cost-effectiveness analysis method is an adaptation of a traditional safety analysis procedure based on the calculation of the cost to achieve a given unit of effect (reduction in collisions). The significant aspects of this procedure are that it need not require the assignment of a dollar value to human injuries or fatalities and requires minimal manpower to apply.

The following steps should be performed for the cost-effectiveness technique:

1. Determine the initial capital cost of equipment, such as flashing lights or gates, and other costs associated with project implementation.

2. Determine the annual operating and maintenance costs for the project.

3. Select units of effectiveness to be used in the analysis. The desired units of effectiveness may be:

• Number of total collisions prevented.

• Number of collisions by type prevented.

• Number of fatalities or fatal collisions prevented.

• Number of personal injuries or personal injury collisions prevented.

• Number of equivalent property-damage-only collisions prevented.

4. Determine the annual benefit for the project in the selected units of effectiveness, such as total number of collisions prevented.

5. Estimate the service life.

6. Estimate the net salvage value.

7. Assume an interest rate.

8. Calculate the equivalent uniform annual costs (EUAC) or present worth of costs (PWOC).

9. Calculate the average annual benefit, B, in the desired units of effectiveness.

10. Calculate the cost-effectiveness (C/E) value using one of the following equations:

where:

CRFni = capital recovery factor for n years at interest rate i

Figure 57 shows a sample worksheet with fictitious values.

This is an iterative process for each alternative improvement. The results for all projects then can be arrayed and compared for selection. A computer program can be used for the analysis and ranking of projects.

2. Benefit-Cost Ratio

The benefit-cost ratio (B/C) is the collision savings in dollars divided by cost of the improvement. Using this method, costs and benefits may be expressed as either an equivalent annual or present worth value of the project. The B/C technique requires the following steps:

• Determine the initial cost of implementation of the crossing improvement being studied.

• Determine the net annual operating and maintenance costs.

• Determine the annual safety benefits derived from the project.

• Assign a dollar value to each safety benefit unit (NSC, NHTSA, or other).

• Estimate the service life of the project based on patterns of historic depreciation of similar types of projects.

• Estimate the salvage value of the project or improvement after its primary service life has ended.

• Determine the interest rate by taking into account the time value of money.

• Calculate the B/C ratio using EUAC and equivalent uniform annual benefits (EUAB).

• Calculate the B/C ratio using PWOC and present worth of benefits (PWOB).

A sample worksheet with fictitious values for the B/C analysis is shown in Figure 58.

This method requires an estimate of collision severity in dollar terms, which can greatly affect the outcome. It is relatively easy to apply and is generally accepted in engineering and financial studies. As with the C/E method, the process can be performed for alternative improvements at a single crossing and arrayed for all projects to determine priorities for funding.

3. Net Annual Benefit

This method is based on the premise that the relative merit of an improvement is measured by its net annual benefit. This method is used to select improvements that will ensure maximum total benefits at each location. The net annual benefit of an improvement is defined as follows:

Net annual benefit = (EUAB) - (EUAC) (13)

where:

EUAB = equivalent uniform annual benefit

EUAC = equivalent uniform annual cost

A positive value for net annual benefit indicates a feasible improvement, and the improvement or set of improvements with the largest positive net annual benefit is considered the best alternative. The following steps should be used to compute the net annual benefit:

• Estimate the initial cost, annual cost, terminal value, and service life of each improvement.

• Estimate the benefits (in dollars) for each improvement.

• Select an interest rate.

• Compute EUAB.

• Compute EUAC.

• Calculate the net annual benefit of each improvement.

For the data and calculations shown in Figure 58, the net annual benefit would be $91,438, determined from EUAB of $104,000 less EUAC of $12,562.

Although any of the three methods is an acceptable procedure to follow for economic analyses, they might produce different results depending on the values. Table 45 illustrates this point. The values shown for the second alternative are from the example provided above. Based on the C/E method, the analyst would select the third alternative. Based on the B/C ratio method, the analyst would select the second alternative. The first alternative would be selected if the net benefit method was followed for this example.

Figure 57. Sample Cost-Effectiveness Analysis Worksheet

Download a PDF file of Figure 57: To view PDF files, you can use the Adobe® Reader®. |

Figure 58. Sample Benefit-to-Cost Analysis Worksheet

Download a PDF file of Figure 58: To view PDF files, you can use the Adobe® Reader®. |

Given that different results can occur, the agency should not follow just one procedure. At least two methods should be followed, with the decision based on these results and other factors, constraints, and policies of the agency.

Table 45. Comparison of Cost-Effectiveness, Benefit-Cost, and Net Benefit Methods

Initial Costs |

Cost-Effectiveness ($/acc.) |

B/C |

Net Benefit |

|

A |

1,000,000 |

106,000 |

2 |

200,000 |

B |

100,000 |

6,281 |

8.3 |

91,438 |

C |

20,000 |

5,100 |

5 |

70,000 |

Source: Railroad-Highway Grade Crossing Handbook, Second Edition. Washington, DC: U.S. Department of Transportation, Federal Highway Administration, 1986.

E. Resource Allocation Procedure

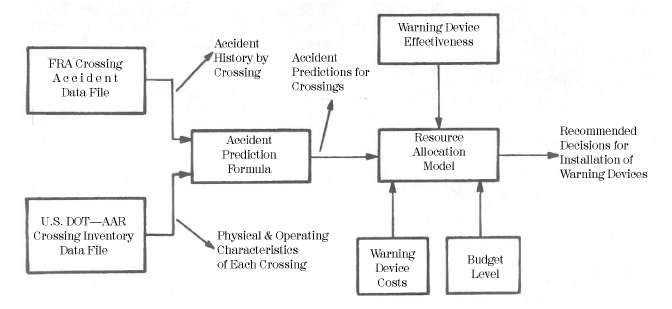

In lieu of the economic analysis procedures described above, U.S. DOT has developed a resource allocation procedure for highway-rail grade crossing improvements. This procedure was developed to assist states and railroads in determining the effective allocation of federal funds for crossing traffic control improvements.

The resource allocation model is designed to provide an initial list of crossing traffic control improvements that would result in the greatest collision reduction benefits on the basis of cost-effectiveness considerations for a given budget. As designed, the results are checked by a diagnostic team in the field and revised as necessary. It should be noted that the procedure considers only traffic control improvement alternatives as described below:

• For passive crossings, single track, two upgrade options exist: flashing lights or gates.

• For passive, multiple-track crossings, the model allows only the gate option to be considered in accordance with the Federal-Aid Policy Guide.

• For flashing light crossings, the only improvement option is gates.

Other improvement alternatives, such as removal of site obstructions, crossing surface improvements, illumination, and train detection circuitry improvements, are not considered in the resource allocation procedure.

The input data required for the procedure consist of the number of predicted collisions, the safety effectiveness of flashing lights and automatic gates, improvement costs, and the amount of available funding.

The number of annual predicted collisions can be derived from the U.S. DOT Accident Prediction Model or from any model that yields the number of annual collisions per crossing. (See discussion in Chapter III.)

Safety effectiveness studies for the equipment used in the resource allocation procedure have been completed by U.S. DOT, the California Public Utilities Commission, and William J. Hedley. The resulting effectiveness factors of these studies were given in Table 40 for the types of signal improvements applicable for the procedure. Effectiveness factors are the percent reduction in collisions occurring after the implementation of the improvement.

The model requires data on the costs of the improvement alternatives. Life-cycle costs of the devices should be used, such as both installation and maintenance costs.

Costs used in the resource allocation procedure must be developed for each of the three alternatives:

• Passive devices to flashing lights.

• Passive devices to automatic gates.

• Flashing lights to gates.

Caution should be exercised in developing specific costs for a few selected projects while assigning average costs to all other projects. If this is done, decisions regarding the adjusted crossings may be unreasonably biased by the algorithm.

The amount of funds available for implementing crossing signal projects is the fourth input for the resource allocation procedure.

The resource allocation procedure is shown in Figure 59. It employs a step-by-step method, using the inputs described above.

For any proposed signal improvement, a pair of parameters, Ej and Cj, must be provided for the resource allocation algorithm. As shown in Table 46, j = 1 for flashing lights installed at a passive crossing; j = 2 for gates installed at a passive crossing; and j = 3 for gates installed at a crossing with flashing lights. The first parameter, Ej, is the effectiveness of installing a proposed warning device at a crossing with a lower class warning device. The second parameter, Cj, is the corresponding cost of the proposed warning device.

Figure 59. Crossing Resource Allocation Procedure

Source: Railroad-Highway Grade Crossing Handbook, Second Edition. Washington, DC: U.S. Department of Transportation, Federal Highway Administration, 1986.

Table 46. Effectiveness/Cost Symbol Matrix

Existing warning device |

||

Proposed warning device |

Passive |

Flashing lights |

Flashing lights |

||

Effectiveness |

E 1 |

— |

Cost |

1 |

— |

Automatic gates |

||

Effectiveness |

E 2 |

E 3 |

Cost |

C 2 |

3 |

Source: Railroad-Highway Grade Crossing Handbook, Second Edition. Washington, DC: U.S. Department of Transportation, Federal Highway Administration, 1986.

The resource allocation procedure considers all crossings with either passive or flashing light traffic control devices for signal improvements. If, for example, a single-track passive crossing, i, is considered, it could be upgraded with either flashing lights, with an effectiveness of E1, or gates, with an effectiveness of E2. The number of predicted collisions at crossing i is Ai. Therefore, the reduced accidents per year is AiE1 for the flashing light option and AiE2 for the gate option. The corresponding costs for these two improvements are C1 and C2. The accident reduction/cost ratios for these improvements are AiE1/ C1 for flashing lights and AiE2/C2 for gates. The rate of increase in accident reduction versus costs that results from changing an initial decision to install flashing lights with a decision to install gates at crossing i is referred to as the incremental accident reduction/cost ratio and is equal to:

Ai (E2 – E1) / (C2 – C1) (14)

If a passive multiple-track crossing, i, is considered, the only improvement option allowable would be installation of gates, with an effectiveness of E2, a cost of C2, and an accident reduction/cost ratio of AiE2/C2. If crossing i was originally a flashing light crossing, the only improvement option available would be installation of gates, with an effectiveness of E3, a cost of C3, and an accident reduction/cost ratio of AiE3/C3.

The individual accident reduction/cost ratios associated with these improvements are selected by the algorithm in an efficient manner to produce the maximum accident reduction that can be obtained for a predetermined total cost. This total cost is the sum of an integral number of equipment costs (C1, C2, and C). The total maximum accident reduction is the sum of the individual accident reductions of the form A E.

The resource allocation procedure is being updated to include the severity prediction equations discussed in Chapter III.

The U.S. DOT Rail-Highway Crossing Resource Allocation Procedure, as described in the Rail-Highway Crossing Resource Allocation Procedure’s Guide, Third Edition (August 1987), uses three “normalizing constants” in the accident prediction formula, Formula A (Section 3.2.4, page 17). These constants need to be adjusted periodically to keep the procedure matched with current collision trends. The last recalculation and adjustment was made for calendar year 1998 and published in the Appendix for the Railroad Safety Statistics Annual Report starting for year 1999.

Using the collision data for calendar years 1997 to 2001 (to predict 2002), the process of determining the three new normalizing constants for 2003 was performed such that the sum of the 2002 accident prediction values of all currently open public at-grade crossings is made to equal the sum of the observed number of collisions that occurred for those same crossings. This process is performed for each of the respective three formulae for the three types of warning device categories: passive, flashing lights, and gates. This process normalized the calculated prediction for the current trend in collision data (downward) for each category and relative to each of the three types of warning device categories (see Table 47).

As of November 2003, these new constants are in the 2003 PC Accident Prediction System (PCAPS) computer program and the Internet version, Web Accident Prediction System (WBAPS), on the FRA Website.119 Table 47 lists the new and prior constants.

If this resource allocation procedure is used to identify high-hazard crossings, a field diagnostic team should investigate each selected crossing for accuracy of the input data and reasonableness of the recommended solution. A worksheet for accomplishing this is included in Figure 60. This worksheet also includes a method for manually evaluating or revising the results of the computer model.

Table 47. Collision Prediction and Resource Allocation Procedure Normalizing Constants

Warning device groups |

New |

Prior years |

||||

2003 |

1998 |

1992 |

1990 |

1988 |

1986 |

|

Passive |

.6500 |

.7159 |

.8239 |

.9417 |

.8778 |

.8644 |

Flashing lights |

.5001 |

.5292 |

.6935 |

.8345 |

.8013 |

.8887 |

Gates |

.5725 |

.4921 |

.6714 |

.8901 |

.8911 |

.8131 |

Source: Federal Railroad Administration Website (safetydata.ra.dot.gov/officeofsafety).

F. Federal Railroad Administration GradeDec Software

FRA developed the GradeDec.NET (GradeDec) highway-rail grade crossing investment analysis tool to provide grade crossing investment decision support. GradeDec provides a full set of standard benefit-cost metrics for a rail corridor, a region, or an individual grade crossing. Model output allows a comparative analysis of grade crossing alternatives designed to mitigate highway-rail grade crossing collision risk and other components of user costs, including highway delay and queuing, air quality, and vehicle operating costs. The online application can be accessed via FRA’s Website.120

GradeDec is intended to assist state and local transportation planners in identifying the most efficient grade crossing investment strategies. The GradeDec modeling process can encourage public support for grade crossing strategies, including closure and separation, where project success often depends on getting the community involved in the early planning stages. GradeDec computes model output using a range of values for many of the model inputs. This process allows individual stakeholders to influence how different investment options are weighed and evaluated.

GradeDec implements the corridor approach to reducing collision risk that was developed as part of the Transportation Equity Act for the 21st Century’s Next-Generation High-Speed Rail Program. This approach can be an effective means of reducing the overall capital costs involved in constructing facilities for high-speed passenger rail service (at speeds between 111 and 125 mph), where grade crossing hazards and mitigation measures can be a major cost factor.

Figure 60. Resource Allocation Procedure Field Verification Worksheet

Download a PDF file of Figure 60: To view PDF files, you can use the Adobe® Reader®. |

The corridor approach can be used to demonstrate that acceptable levels of collision risk have been reached for all rail corridors, train types, and speeds. For example, exceptions to the proposed federal rule mandating whistle-sounding at all highway-rail grade crossings can be made by showing that appropriate safety measures have been taken to mitigate the additional risk otherwise presented by trains not sounding their horns.

GradeDec uses simulation methods to analyze project risk and generate probability ranges for each model output, including B/C ratios and net present value. The software also analyzes the sensitivity of project risk to GradeDec 2000 model inputs to inform users which factors have the greatest impact on project risk.121

The Effectiveness of Automatic Protection in Reducing Accident Frequency and Severity at Public Grade Crossings in California. San Francisco, California: California Public Utilities Commission, June 1974.

Guidance on Traffic Control Devices At Highway-Rail Grade Crossings. Washington, DC: FHWA, Highway/Rail Grade Crossing Technical Working Group, 2002.

Highway Safety Improvement Program User’s Manual. Washington, DC: Federal Highway Administration (FHWA).

Hitz, John and Mary Cross. Rail-Highway Crossing Resource Allocation Procedure User’s Guide. Washington, DC: FHWA and Federal Railroad Administration (FRA), Report FHWA-IP-82-7, December 1982.

Morrissey, J. The Effectiveness of Flashing Lights and Flashing Lights with Gates in Reducing Accident Frequency at Public Rail-Highway Crossings, 1975-1978. Washington, DC: FRA and FHWA, April 1980.

118 Guidance on Traffic Control Devices at Highway-Rail Grade Crossings. Washington, DC: Federal Highway Administration (FHWA), Highway/Rail Grade Crossing Technical Working Group, November 2002.

119 Federal Railroad Administration (FRA) Website (safetydata.fra.dot.gov/officeofsafety).

120 FRA Website (gradedec.fra.dot.gov).

121 FRA GradeDec 2000 program for evaluating costs/benefits of railroad-highway grade crossing investments (www.fra.dot.gov/us/content/1195).

| Table of Contents | Previous | Next |