| Railroad-Highway Grade Crossing Handbook - Revised Second Edition August 2007 | |

| Section 2: Components of a Highway-Rail Grade Crossing | Table of Contents | Previous | Next |

II

Components of a Highway-Rail Grade Crossing

A highway-rail grade crossing can be viewed as simply a special type of highway intersection, in that the three basic elements of any intersection are present: the driver, the vehicles, and the physical intersection. As with a highway intersection, drivers must appropriately yield the right of way to opposing traffic; unlike a highway-highway intersection, the opposing traffic—the train—must only rarely yield the right of way to the highway vehicle. Drivers of motor vehicles have the flexibility of altering their path of travel and can alter their speed within a short distance. Train operators, on the other hand, are restricted to moving their trains down a fixed path, and changes in speed can be accomplished much more slowly. Because of this, motorists bear most of the responsibility for avoiding collisions with trains.

The railroad crossbuck sign is defined in the Manual on Uniform Traffic Control Devices (MUTCD) as a regulatory sign.37 In effect, it is a YIELD sign, and motorists have the obligation to so interpret it. (Refer to the discussion on the use of STOP and YIELD signs in Chapter IV.) Traffic and highway engineers can assist motorists with the driving task by providing them with proper highway design, adequate sight distances, and proper traffic control devices.

The components of a highway-rail grade crossing are divided into two categories: the highway and the railroad. The highway component can be further classified into several elements including the roadway, drivers, pedestrians and bicyclists, and vehicles. The railroad component is classified into train and track elements. The location where these two components meet must be designed to incorporate the basic needs of both highway vehicles and trains.

Traffic control devices are utilized to provide road users with information concerning the crossing. Typically, an advance warning sign and pavement markings inform the motorist that a crossing lies ahead in the travel path. The crossing itself is identified and located by the use of the crossbuck. These traffic control devices—the advance sign, pavement markings, and crossbuck—are termed “passive” because their message remains constant with time.

“Active” traffic control devices tell the motorist whether or not a train is approaching or occupying a crossing and, thus, give a variable message. Typical active traffic control devices are flashers or flashers and automatic gates. A highway traffic signal may also be interconnected to the crossing signals and would form part of the traffic control system at the crossing.

The U.S. Department of Transportation (U.S. DOT) National Highway-Rail Crossing Inventory provides information on the number of crossings having each type of traffic control device, as shown in Table 7.

* Includes previously unpublished materials provided by Ray Lewis, West Virginia Department of Transportation (WVDOT), 2006.

The driver is responsible for obeying traffic control devices, traffic laws, and the rules of the road. Highway and railroad engineers who plan and design initial installations or later improvements to traffic control systems at railroad grade crossings should be aware of the several capabilities, requirements, needs, and obligations of the driver. This information will help them, through the proper engineering design of improvements, assist drivers in meeting their responsibilities.

Table 7. Public Crossings by Warning Device, 2004

Warning device |

Number |

Percent |

Active devices |

||

Gates |

36,760 |

24.87 |

Flashing lights |

25,081 |

16.97 |

Highway signals, wigwags, or bells |

1,217 |

0.82 |

Special* |

2,912 |

1.97 |

Total active |

65,970 |

44.63 |

Passive devices |

||

Crossbucks |

66,463 |

44.97 |

STOP signs |

10,189 |

6.89 |

Other signs |

687 |

0.47 |

Total passive |

77,339 |

52.33 |

No signs or signals |

4,496 |

3.04 |

Total |

147,805 |

100.00 |

* Note: “Special” are traffic control systems that are not train activated, such as a crossing being flagged by a member of the train crew.

Source: Unpublished data from Federal Railroad Administration.

Much of the information regarding driver characteristics and capabilities is covered in Chapter III and need not be stated here. This section deals with the duties of the motor vehicle driver.

The Uniform Vehicle Code (UVC) is a specimen set of motor vehicle laws designed or advanced as a comprehensive guide or standard for state motor vehicle and traffic laws.38 It describes the actions a driver is required to take at highway-rail grade crossings. The UVC defines the “appropriate actions” vehicle operators are required to take for three situations: vehicle speed approaching the crossing; vehicle speed traversing the crossing; and stopping requirements at the crossing. The provisions in UVC for these actions are set out below:

• Approach Speed (Sec. 11-801)

No person shall drive a vehicle at a speed greater than is reasonable and prudent under the conditions and having regard to the actual and potential hazards then existing. Consistent with the foregoing, every person shall drive at a safe and appropriate speed when approaching and crossing an intersection and railroad grade crossing . . .

• Passing (Sec. 11-306)

(a) No vehicle shall be driven on the left side of the roadway under the following conditions ...

... When approaching within 100 feet of or traversing any intersection or railroad grade crossings unless otherwise indicated by official traffic control devices . . .

• Vehicles Approaching a Highway-Rail Grade Crossing (Sec. 11-702)

(a) Whenever a road user approaches a highway-rail grade crossing under any of the five circumstances enumerated in this subsection, the driver shall stop before the stop line (if present) and not less than 15 feet from the nearest rail of the track, and while so stopped shall listen and look in both directions along such track for signals indicating the approach of a train or other vehicle, and shall not proceed until it is safe to do so. The foregoing requirements shall apply when any of the following occur:

o An approaching train is visible and in hazardous proximity to such crossing.

o A clearly visible electric or mechanical signal device gives warning of the immediate approach of a railroad train;

o A stop sign or other traffic control device requiring a stop is posted at the crossing;

o A crossing gate is lowered or is being lowered or raised, or a human flagger gives or continues to give a signal of the approach or passage of a railroad train; or

o An approaching train horn is being sounded.

(b) Except for the five instances requiring a stop listed in subsection (a) or unless otherwise specified by law, regulation or the directions of a police officer, flagger or a traffic control device, a person driving a vehicle approaching a highway-rail grade crossing shall yield the right of way to any train within the crossing or approaching so closely as to constitute an immediate hazard during the time such driver is moving across or within the crossing. After stopping or yielding as required herein and proceeding when it is safe to do so, the driver shall cross only in a gear of the vehicle that will not require manually changing gears while traversing such crossing and the driver shall not manually shift gears while crossing the track or tracks.

Designated Vehicles Must Stop at Highway-Rail Grade Crossings (11-703)

(a) Except as provided in subsection (b), the driver of any vehicle described in regulations issued pursuant to subsection (c), before crossing at grade any track or tracks of a railroad, shall stop such vehicle before the stop line (if present) and not less than 15 feet from the nearest rail of such track, and while so stopped shall listen and look in both directions along such track for any approaching train and for signals indicating the approach of a train and shall not proceed until it is safe to do so. After stopping as required, upon proceeding when it is safe to do so, the driver shall cross only in a gear of the vehicle that will not require manually changing gears while traversing such crossing and the driver shall not manually shift gears while crossing the track or tracks.

(b) This section shall not apply at any highway-rail grade crossing:

1. Controlled by a police officer or flagger;

2. At which an official traffic control device provides notice that the stopping requirement imposed by this section shall not apply;

3. A streetcar crossing, or railroad tracks used exclusively for industrial switching purposes, within a business district;

4. An abandoned railroad grade crossing which is marked with a sign indicating that the rail line is abandoned;

5. An industrial or spur line railroad grade crossing marked with a sign reading “Exempt.” Such “Exempt” signs shall be erected only by or with the consent of the appropriate State or local authority.

(c) The (commissioner or other appropriate State official or agency) shall adopt regulations, as may be necessary, describing the vehicles that must comply with the stopping requirements of this section. In formulating those regulations, the (commissioner or other appropriate State official or agency) shall consider the operating characteristics of the vehicle, the number of passengers carried, and the hazardous nature of any substance carried in determining whether such vehicle shall be required to stop.

The UVC also prohibits any vehicle from driving around or under any gate or barrier while it is closed or being opened or closed.

Each state has its own traffic laws, which may vary from those above. The pertinent sections of the state code and the state driver licensing handbook should be consulted for more information.

The design and operation of a railroad grade crossing must take into account the numbers and types of vehicles that can be expected to use it. In this regard, crossings are exposed to the full array of vehicle types found on highways, from motorcycles to truck tractor/triple-trailer combinations, although the use of crossings by the largest vehicle types is rare. Typically, the largest vehicles that will use an at-grade crossing are full-size passenger buses or design trucks such as WB-50. The vehicles utilizing highway-rail grade crossings have widely different characteristics that will directly influence the design elements of the crossing. Equally important is the cargo these vehicles carry, especially children in school buses and hazardous materials in trucks.

Table 8 summarizes collisions at crossings by vehicle type. Rates are defined as collisions per billion miles of travel. The data provide some indication of the relative hazards for each of the vehicles. Trucks have the highest collision rates of all vehicle types. Motorcycles have a higher fatality rate, probably because of the lack of operator protection provided by the vehicle.

Table 8. Motor Vehicle Collisions and Casualties at Public Crossings by Vehicle Type, 2004

Automobiles1 |

Buses |

Trucks2 |

Motorcycles |

Total |

|

Total collisions |

|||||

Number |

1,828 |

7 |

587 |

9 |

2,431 |

Rate3 |

0.67 |

1.05 |

2.59 |

0.90 |

0.84 |

Percent |

75.19 |

0.29 |

24.15 |

0.37 |

100.00 |

Total fatalities |

|||||

Number |

204 |

0 |

35 |

2 |

241 |

Rate3 |

0.08 |

0.00 |

0.15 |

0.20 |

0.08 |

Percent |

84.65 |

0.00 |

14.52 |

0.83 |

100.00 |

Total injuries |

|||||

Number |

648 |

7 |

225 |

5 |

885 |

Rate3 |

0.24 |

1.05 |

0.99 |

0.50 |

0.31 |

Percent |

73.22 |

0.79 |

25.42 |

0.57 |

100.00 |

Vehicle miles of travel (billions) |

2,719.32 |

6.64 |

226.51 |

10.05 |

2,890.89 |

Registered vehicles |

228,276,000 |

795,000 |

8,171,000 |

5,781,000 |

236,761,000 |

Collisions per million vehicles |

8.01 |

8.81 |

71.84 |

1.56 |

10.27 |

1 “Automobiles” includes passenger cars, pick-up trucks, vans, and sport utility vehicles.

2 “Trucks” includes both single-unit trucks and combination trucks.

3 “Rate” is the number of collisions, fatalities, or injuries divided by billions of vehicle miles traveled.

Source: Railroad Safety Statistics Annual Report 2004. Bureau of Transportation Statistics Website (www.bts.gov).

Several physical and performance characteristics influence the safety of vehicles at crossings. These include vehicle dimensions, braking performance, and acceleration performance.

Vehicle dimensions. The length of a vehicle has a direct bearing on the inherent safety of the vehicle at a grade crossing and, consequently, is an explicit factor considered in the provision of sight distances. Long vehicles and vehicles carrying heavy loads have longer braking distances and slower acceleration capabilities; hence, long vehicles may be exposed to a crossing for an even greater length of time than would be expected in proportion to their length.

Vehicle length is explicitly considered in determining the effect of sight distance and the corner sight triangle on the safe vehicle approach speed toward the crossing and in determining the sight distance along the track for vehicles stopped at the crossing. The design lengths of various vehicles are specified by the American

Association of State Highway and Transportation Officials (AASHTO) and shown in Tables 9 and 10.

AASHTO now recognizes a total of 20 design vehicle classes. This reflects the increase in the size of tractor-semitrailers, which began with the passage of the Surface Transportation Assistance Act of 1982, as well as the increasing presence of articulated buses in the U.S. transit fleet and the increasing popularity of recreational vehicles and motor homes.39

Unless trucks are prohibited at the crossing, it is desirable that the design vehicle be at least a tractor-semitrailer truck (WB-15 SI Metric, or WB-50). Typically, the design vehicle should be a “double-bottom” vehicle (WB-18 SI Metric, or WB-60) for those crossings on routes designated for longer trucks, although consideration should be given especially to long vehicles where applicable. On major arterials with significant truck traffic, the design vehicle should be an “interstate” semitrailer truck (WB-62 or WB-65).

Table 9. U.S. Customary Lengths for Design Vehicles

Design vehicle type |

Designation |

Length (feet) |

Passenger car |

P |

19 |

Single-unit truck |

SU |

30 |

Buses |

||

Intercity bus (motor coaches) |

BUS-40 |

40 |

BUS-45 |

45 |

|

City transit bus |

CITY-BUS |

40 |

Conventional school bus (65 passengers) |

S-BUS 36 |

35.8 |

Large school bus (84 passengers) |

S-BUS 40 |

40 |

Articulated bus |

A-BUS |

60 |

Trucks |

||

Intermediate semitrailer |

WB-40 |

45.5 |

Intermediate semitrailer |

WB-50 |

55 |

Interstate semitrailer |

WB-62* |

68.5 |

Interstate semitrailer |

WB-65** or WB-67 |

73.5 |

“Double-bottom” semitrailer/trailer |

WB-67D |

73.3 |

Triple-semitrailer/trailers |

WB-100T |

104.8 |

Turnpike double-semitrailer/trailer |

WB-109D* |

114 |

Recreational vehicles |

||

Motor home |

MH |

30 |

Car and camper trailer |

P/T |

48.7 |

Car and boat trailer |

P/B |

42 |

Motor home and boat trailer |

MH/B |

53 |

Farm tractor*** |

TR |

16 |

* Design vehicle with 48-foot trailer as adopted in the 1982 Surface Transportation Assistance Act.

** Design vehicle with 53-foot trailer as adopted grandfathered in with the 1982 Surface Transportation Assistance Act.

*** 150–200 horsepower tractor excluding any wagon length.

Source: From A Policy on Geometric Design of Highway and Streets, 2004, by the American Association of State Highway and Transportation Officials, Washington, DC. Used by permission.

The width of the vehicle may be an issue when selecting the crossing surface. Since the passage of the 1982 Surface Transportation Assistance Act, trucks and intercity buses are permitted to have widths of 2.6 meters (102 inches).

Braking performance. One component of stopping sight distance is a function of a vehicle’s braking performance. If a crossing experiences a significant percentage of heavy trucks, any given sight distance will dictate a slower speed of operation to allow for the braking performance of these vehicles.

Acceleration performance. Acceleration of vehicles is important to enable a stopped vehicle to accelerate and clear the crossing before a train that was just out of sight or just beyond the train detection circuitry reaches the crossing. Large trucks that have relatively poor acceleration capabilities coupled with long lengths are particularly critical in this type of situation.

There are three phases of operation for a truck that has stopped at a crossing: start-up when the clutch is being engaged; acceleration from the point of full clutch engagement; and continued travel until the crossing is cleared.

Another aspect of the acceleration performance of vehicles at crossings is the design of the crossing approaches coupled with the condition of the crossing surface. Crossings and approaches on a steep grade are difficult and time-consuming to cross. Also, vehicles will move more slowly over crossings that have rough surfaces.

Special vehicles. Three vehicle types are of particular concern for crossing safety: trucks carrying hazardous materials; any commercial motor vehicle transporting passengers; and school buses. Collisions involving these vehicles can result in numerous injuries and/or fatalities, perhaps in catastrophic proportions if certain hazardous cargoes are involved.

Table 10. Metric Lengths for Design Vehicles

Design vehicle type |

Designation |

Length (meters) |

Passenger car |

P |

5.8 |

Single-unit truck |

SU |

9.2 |

Buses |

||

Intercity bus (motor coaches) |

BUS-12 |

12.2 |

BUS-14 |

13.7 |

|

City transit bus |

CITY-BUS |

12.2 |

Conventional school bus (65 passengers) |

S-BUS 11 |

10.9 |

Large school bus (84 passengers) |

S-BUS 12 |

12.2 |

Articulated bus |

A-BUS |

18.3 |

Trucks |

||

Intermediate semitrailer |

WB-12 |

13.9 |

Intermediate semitrailer |

WB-15 |

16.8 |

Interstate semitrailer |

WB-19* |

20.9 |

Interstate semitrailer |

WB-20** |

22.4 |

“Double-bottom” semitrailer/trailer |

WB-20D |

22.4 |

Triple-semitrailer/trailers |

WB-30T |

32.0 |

Turnpike double-semitrailer/trailer |

WB-33D |

34.8 |

Recreational vehicles |

||

Motor home |

MH |

9.2 |

Car and camper trailer |

P/T |

14.8 |

Car and boat trailer |

P/B |

12.8 |

Motor home and boat trailer |

MH/B |

16.2 |

Farm tractor*** |

TR |

4.9 |

* Design vehicle with 14.63-meter trailer as adopted in the 1982 Surface Transportation Assistance Act.

** Design vehicle with 16.16-meter trailer as adopted grandfathered in with the 1982 Surface Transportation Assistance Act.

*** 150–200 horsepower tractor excluding any wagon length.

Source: From A Policy on Geometric Design of Highway and Streets, 2004, by the American Association of State Highway and Transportation Officials, Washington, DC. Used by permission.

In a special study conducted by the National Transportation Safety Board (NTSB), it was determined that an average of 62 collisions involving train collisions with trucks transporting hazardous materials occur annually. NTSB’s examination of the collision data revealed that these collisions tend to occur near truck terminals.40

Requirements for commercial vehicles to stop or slow at highway-rail grade crossings are contained in 49 CFR Part 392.10, which requires that the driver of a specified commercial motor vehicle:

Shall not cross a railroad track or tracks at grade unless he/she first: Stops the commercial motor vehicle within 50 feet of, and not closer than 15 feet to, the tracks; thereafter listens and looks in each direction along the tracks for an approaching train; and ascertains that no train is approaching. When it is safe to do so, the driver may drive the commercial motor vehicle across the tracks in a gear that permits the commercial motor vehicle to complete the crossing without a change of gears. The driver must not shift gears while crossing the tracks.

Vehicles to which this rule pertains include but are not limited to:

• Every bus transporting passengers and vehicles transporting migrant workers. (“Bus” is defined at 49 CFR 390.5 as “as any motor vehicle designed, constructed, and or used for the transportation of passengers, including taxicabs.”)

• Every commercial motor vehicle which, in accordance with the regulations of U.S. DOT, is required to be marked or placarded with hazardous materials including:

0 |

Poison Gas. |

0 |

Flammables. |

0 |

Chlorine. |

0 |

Poison. |

0 |

Oxygen. |

0 |

Combustible liquids. |

Exceptions provided in the rule indicate a stop need not be made at:

• A streetcar crossing, or railroad tracks used exclusively for industrial switching purposes, within a business district;

• A railroad grade crossing when a police officer or crossing flagman directs traffic to proceed;

• A railroad grade crossing controlled by a functioning highway traffic signal transmitting a green indication which, under local law, permits the commercial motor vehicle to proceed across the railroad tracks without slowing or stopping;

• An abandoned railroad grade crossing marked with a sign indicating that the rail line is abandoned; or

• An industrial or spur line railroad grade crossing marked with a sign reading “Exempt.” Such signs shall be erected only by or with the consent of the appropriate state or local authority.

As required by §398.4, all such motor vehicles shall display a sign on the rear reading, “This Vehicle Stops at Railroad Crossings.”

Finally, Part 392.11 provides that:

Every commercial motor vehicle other than those listed in §392.10 shall, upon approaching a railroad grade crossing, be driven at a rate of speed which will permit said commercial motor vehicle to be stopped before reaching the nearest rail of such crossing and shall not be driven upon or over such crossing until due caution has been taken to ascertain that the course is clear.

Provisions to enhance safety for these special vehicles are further discussed in Chapter IX, Special Issues.

In 2004, collisions involving pedestrians at crossings accounted for only 3.6 percent, or 111, of all crossing collisions. As can be expected, these collisions almost always result in an injury or fatality. In 2004, there were 73 pedestrian fatalities, comprising 6.8 percent of all crossing fatalities. These statistics do not include pedestrian collisions occurring elsewhere along railroad tracks. Excluding collisions and incidents at crossings, 482 trespasser fatalities occurred on railroad property during 2004. This represents 54 percent of all railroad-related fatalities.

Table 11 shows the number of highway-rail grade crossing collision fatalities and trespasser fatalities from 1995 to 2004. During this 10-year period, crossing collision fatalities steadily decreased while trespasser fatalities remained generally constant. Each year since 1997, the number of trespasser fatalities has been greater than the number of highway-rail grade crossing collision fatalities.

Table 11. Highway-Rail Grade Crossing Collision Fatalities versus Trespasser Fatalities, 1995–2004

Year |

Highway-rail grade |

Trespasser fatalities |

1995 |

579 |

494 |

1996 |

488 |

471 |

1997 |

461 |

533 |

1998 |

431 |

536 |

1999 |

402 |

479 |

2000 |

425 |

463 |

2001 |

421 |

511 |

2002 |

357 |

540 |

2003 |

334 |

500 |

2004 |

368 |

482 |

Source: Federal Railroad Administration Safety Data Website (safetydata.fra.dot.gov/officeofsafety).

One difference between the driver and a pedestrian at a grade crossing is the relative ease with which a pedestrian can enter the trackway even if pedestrian gates are provided.

It is important to understand four contributing factors that may motivate pedestrians to enter railroad right of way to establish effective preventive measures. First, as a consequence of urban development, railroads often act as physical dividers between important, interrelated elements of communities.

Second, railroads have always attracted juveniles as “play areas.” Third, at or near commuter stations, passengers frequently use short cuts before or after boarding a train. Fourth, some people are prone to vandalism.41

Several types of preventive measures might be employed, including:

• Fencing or other devices for enclosing rights of way.

• Grade separation.

• Additional signing.

• Safety education.

• Surveillance and enforcement.

These measures are discussed in more detail in Chapter IX, Special Issues.

There is renewed interest in pedestrian treatments. Light-rail operators have been deploying various devices to address pedestrian concerns (refer to Chapter IX.) The National Committee on Uniform Traffic Control Devices (NCUTCD), at its January 2006 meeting, established a Pedestrian Task Force on the Railroad Technical Committee, which is charged with developing language that will provide guidance and options for a wider array of pedestrian treatments at grade crossings.

A major component of the crossing consists of the physical aspects of the highway on the approach and at the crossing itself. The following roadway characteristics are relevant to the design and control of highway-rail grade crossings:

• Location—urban or rural.

• Type of road—arterial, collector, or local.

• Traffic volumes.

• Geometric features—number of lanes, horizontal and vertical alignment, sight distance, crossing angle, etc.

• Crossing surface and elevation.

• Nearby intersecting highways.

• Illumination.

Urban crossings often carry more vehicular traffic than rural crossings and have sight restrictions due to developed areas. Urban crossings also involve obstructions to continuous traffic flow, such as controlled intersections, driveways, business establishments and distracting signs, significant lane interaction, and on-street parking.

All other factors being the same, especially train volumes, collision frequency increases with increasing traffic volume. However, traffic volume alone is not a sufficient forecaster of collisions at crossings. This will be shown when collision prediction models are discussed in Chapter III, Assessment of Safety and Operations.

The geometric features that can affect traffic operations at highway-rail grade crossings include:

• Number of lanes and pavement width.

• Horizontal and vertical alignment.

• Crossing angle.

• Crossing elevation.

These features, in turn, affect sight distances to and at crossings.

Number of lanes. Only 7 percent of all public crossings are on highways with more than two lanes.42 It is not known how many crossings with two lanes have an approach width greater than two lanes. The reduction of lanes at a crossing can cause vehicle-vehicle collisions as well as collisions with trains.

At two-lane crossings, a pullout lane may be provided for trucks or buses that may be required to stop for the crossing. By providing a pullout lane, the likelihood of rear-end collisions may be reduced.

Crossings with more than two lanes are usually candidates for cantilevered flashing light signals to improve the visibility of the signals for drivers.

Vertical and horizontal alignment. Sight distance to the crossing is affected by the vertical and horizontal alignment of the crossing and by the crossing angle. Crossings located around a curve or over the crest of a hill may require special attention from the motorist and may need additional signing or active advance warning devices.

Crossing and approach surfaces. The roughness of a crossing surface and the profile of the surface and its approaches may be major areas of concern for road users. A rough surface may contribute to a collision by diverting the road user’s attention from the prime tasks of observing the crossing signals and looking for a train.

Crossing elevation or profile. Another aspect of the crossing is its elevation. Vehicles that must cross the tracks from a stopped position cannot accelerate quickly on steep grades. In addition, trucks with low ground clearances may become trapped on high-profile or “hump-backed” crossings, delaying highway and rail traffic and, possibly, being struck by a train.

Intersecting highways. Approximately one-third of all public highway-rail crossings have a highway intersection within 23 meters (75 feet) of the tracks. Frequently, roads parallel the railroad and intersecting roads intersect the railroad, resulting in a crossing near the highway intersection.

The higher occurrence of collisions at these intersections is due in part to a short storage area for vehicles waiting to move through the crossing and the intersection. If the intersection is signalized or if the approach from the crossing is controlled by a STOP sign, queues may develop across the crossing, leading to the possibility of a vehicle becoming “trapped” on the crossing. Also, there are more distractions to the motorist, leading to the possibility of vehicle-vehicle conflicts.

Crossings within a close distance to a signalized or STOP-controlled intersection should be carefully evaluated for proper controls. STOP controls should be evaluated where either the crossing or the intersection, or both, is not signalized. Traffic signal timing should be carefully evaluated, and an interconnection circuit installed if needed. Joint inspections of interconnected or preempted signals by the railroad and the highway agency must be made on a regular basis to assure that the crossing signals and the highway traffic signal are functioning properly and that the phasing and timing plans are still appropriate.

The critical distance between a highway-rail crossing and a highway-highway intersection is a function of the number of vehicles expected to be queued up by the intersection traffic control.

Illumination. Illumination of the crossing can definitely aid the motorist. In 2004, 1,214 of 3,063 total collisions at crossings occurred during darkness.43 Illumination may be effective in reducing collisions at night; it will also assist road users, including bicyclists and pedestrians, in traversing the crossing at night. U.S. DOT inventory reports that commercial power is available at more than 90 percent of public crossings. Therefore, lighting is feasible at most crossings; depending, of course, on the reliability of the power source. Design details of illumination are discussed in Chapter I V, Identification of Alternatives.

Traffic control systems for highway-rail grade crossings include all signs, signals, markings, and illumination devices and their supports along highways approaching and at railroad crossings at grade. The function of these devices is to permit safe and efficient operation of highway and rail traffic over crossings.

The responsibility for the design, placement, operation, and maintenance of traffic control devices normally rests with the governmental body having jurisdiction over the road or street. For the purpose of installation, operation, and maintenance of devices constituting traffic control devices at highway-rail grade crossings, it is recognized that any crossing of a public road with a railroad is situated on right of way that is available for the use of both highway traffic and railroad traffic on their respective roadway and tracks. This requires joint responsibility in the traffic control function between the public agency and the railroad.

The determination of need and the selection of devices at a grade crossing are normally made by the public agency having jurisdiction. Subject to such determination, the design, installation, and operation of such devices shall be in accordance with the principles and requirements set forth in MUTCD.44

Due to the character of operations and the potentially severe consequences of collisions, traffic control devices at highway-rail grade crossings and on the approaches thereto must be viewed as a system. The combination of approach signs and pavement markings on the roadway approach and the crossbucks or signals at the crossing provides the road user with multiple notices of the presence of the crossing and the likelihood of encountering a train.

For those sections where rail tracks run within a roadway, which is a common practice for light rail and streetcar operations, traffic control may be provided by a combination of signs, pavement markings, and typical “highway” type control devices such as STOP signs and traffic signals. However, for the broader case, where rail tracks are located in a separate right of way with designated crossings of highways and pedestrian pathways, traffic is typically controlled with one of three types of devices, each requiring a distinct compliance response per the UVC, various Model Traffic Ordinances and state regulations:

• A crossbuck is a type of YIELD sign: The driver should be prepared to stop at least 4.5 meters (15 feet) before the near rail if necessary, unless and until the driver can make a reasonable decision that there are no trains in hazardous proximity to the crossing and it is safe to cross.

• Operating flashing lights have the same function as a STOP sign: A vehicle is required to stop completely at least 4.5 meters (15 feet) short of the near rail. Then, even though the flashing lights may still be operating, the driver is allowed to proceed after stopping (subject to state or local laws), when safe to do so.

• Flashing lights with lowered gates are equivalent to a red vehicular traffic signal indication: A vehicle is required to stop short of the gate and remain stopped until the gates go up.

Motorist comprehension and compliance with each of these devices is mainly a function of education and enforcement. The traffic engineer should make full use of the various traffic control devices as prescribed in MUTCD to convey a clear, concise, and easily understood message to the driver that should facilitate education and enforcement.45

A railroad’s class is determined by its inflation-adjusted operating revenues for three consecutive years, using the following scale (2004 amounts):

• Class I: $250 million or more.

• Class II: less than $250 million but more than $20 million.

• Class III: $20 million or less.

Using the inflation-adjusted index, the year 2005 threshold for a Class I railroad is $289.4 million. In 2005, there were seven U.S. Class I railroads:

• BNSF Railway.

• CSX Transportation.

• Grand Trunk Corporation.

• Kansas City Southern Railway.

• Norfolk Southern Combined Railroad Subsidiaries.

• Soo Line Railroad.

• Union Pacific Railroad.

Two Canadian railroads, Canadian National Railway and Canadian Pacific Railway, have enough revenue that they would be U.S. Class I railroads if they were U.S. companies. Both companies also own railroads in the Unites States that, by themselves, qualify to be Class I railroads.

In 2004, there were some 21 Class II railroads.

In 2004, there were about 525 Class III line-haul railroads and switching and terminal companies, also Class III. Many of these Class III railroads provide switching and terminal services for the larger Class I and II railroad companies. Some Class III railroads take over the operation of a single line that a larger railroad abandoned for economic reasons. Class III railroads often require assistance with regard to highway-rail grade crossings because of their limited manpower and financial resources. These small railroads are often unable to seek out federal and state funds for improving crossings, but safety at their crossings is just as important as at any other crossing.

For the purposes of this handbook, the railroad components of highway-rail grade crossings have been divided into two categories: train and track.

During every business day, approximately 112,000 freight cars are loaded in the United States, Canada, and Mexico.46 Statistics as to the average length, net lading, and overall speed of freight trains in a typical year do not begin to describe the variety of operations involved in railroad freight movements. Unit trains may cover more than 1,500 miles without a change of consist and gross from 6,500 to 13,500 tons; a car in a local freight may move only a couple of miles and represent the entire train consist. Dedicated piggyback trains may be limited to 25 to 50 cars and may run over several railroads with few, if any, intermediate stops to set out and pick up blocks of cars at major terminals. This variation in rail movements also occurs on the micro scale, such as at individual highway-rail grade crossings. Thus, the design of traffic control systems at crossings must allow for a wide variation in train length, train speed, and train occurrence.

Long trains, such as unit trains, directly affect the operation of highway traffic over crossings and indirectly affect safety as well. Unit trains consist of as many as 100 freight cars with the same lading. Coal and grain are two major commodities transported in unit trains. Because of their lengths, unit trains will take longer to pass over a crossing and, in effect, close the crossing to highway traffic for a longer period of time.

In addition, some communities have passed ordinances restricting train speed for the purpose of improving safety. However, this practice directly reduces the level of service for highway traffic and may also affect safety. Because of the longer period of time during which the crossing is closed to highway traffic, a motorist may take risks by passing over the crossing just ahead of a train. In many cases, risks such as these are not successful, and collisions result.

Trains other than unit trains typically consist of a variety of cars and ladings. A few cars may be picked up along the way and may be dropped off from the same train or may be taken to a railroad yard where a new train is made up of cars with similar destinations. It is obvious that trains must stop to pick up cars, but it is unfortunate that some of these pick-up points are located in the central portion of communities. This results in trains moving slowly over the crossing or even standing on the crossing as the pick-up is made. With the lengths of freight trains today, an entire community can be physically divided by a freight train stopped on all of its crossings.

Railroads have operating procedures designed to prevent extensive blockage of crossings, and many states have passed regulations prohibiting the blockage of crossings for various lengths of time. Twenty-eight states expressly prohibit trains from blocking crossings for a period that varies from 5 to 20 minutes. Of these, 10 states exempt moving trains.47 A freight train can be divided to allow highway traffic to pass through, but this practice requires the braking system to be filled with air, which can take considerable time. Changes in operating practices that may assist in the alleviation of these types of problems are discussed further in Chapter I V, Identification of Alternatives.

Railroads carry passengers in addition to freight, although this mode of transportation has declined during recent decades due to the construction of the interstate highway system, the convenience of the automobile, and the speed of the airplane. Amtrak, the National Railroad Passenger Corporation, provides passenger service nationwide. Created by Congress in 1971, Amtrak operates over track owned by itself (primarily in the northeast) and by other railroad companies. In accordance with labor agreements, employees of privately-owned railroad companies operate Amtrak passenger trains over that railroad’s trackage.

Some private railroad companies continue to operate passenger trains, particularly for commuter service in urban areas. Some municipal, regional, and state authorities have taken over railroad commuter services. Many light-rail transit companies are in operation and are being constructed in the United States with numerous crossings and longitudinal street use. (These are not normally considered railroads in tabulating crossing collisions.) On the heavy-rail rapid transit systems, there are few crossings of public highways at grade.

Locomotives and cars obviously form a train, but for crossing purposes, any rail operation over a highway is of concern, whether it is one or more engines or a group of cars pushed over a crossing. Most locomotives today are diesel-electric or straight electric, although some railroads operate steam locomotives as special passenger trains for historical purposes. In 1983, 25,838 locomotive units were in service on Class I railroads; all but 63 of these units were diesel-electric.

Headlights. All locomotives are equipped with headlights that are illuminated whenever the locomotive is in motion. One type of light is a 30-volt, 200-watt PAR-56 sealed beam lamp with an output of 200,000 to 300,000 candlepower. The lamp is usually used in pairs. Some railroads use oscillating headlights, comprising one or more standard locomotive headlight lamps on a mounting plate moved by a small motor in a figure eight, circular, or oval pattern. The light beam thus “sweeps” across the tracks.

Several types of roof lights are sometimes used on locomotives to serve as markers in yards so that the locomotive can be easily located among numerous freight cars. These types of roof lights include beacon lights, strobe lights, and sequentially flashing lights. In an effort to make the locomotive as visible as possible, some railroads utilize these types of lights at highway-rail grade crossings, either illuminating them whenever the locomotive is in motion or illuminating them in advance of crossings.

The Federal Railroad Administration (FRA) considered a regulation that would require the mandatory use of strobe lights or, in a later proposed rulemaking, the use of any of the four types of roof lights at crossings. However, based on information received in response to the proposed rulemakings and on an in-depth analysis of costs and benefits, FRA concluded that the information in the docket does not support the proposition that alerting lights are effective in reducing the incidence of grade crossing collisions. Without that support, a federal regulatory requirement that railroads equip their locomotives with an alerting light is not justified.48

FRA issued a Final Rule on locomotive headlights, 49 CFR 229, effective March 16, 2004, which clarified FRA requirements for locomotive lighting, including the requirement for auxiliary lighting. The revised regulations are in Section 229.125, and the auxiliary lights are to be placed at the front of the locomotive to form a triangle with the headlight.49

Train horns and quiet zones. Locomotives are equipped with air-powered horns to sound a warning of a train’s approach to a crossing and for various other signals in railroad operations. Under current rules, FRA requires the horn to produce a minimum sound level of 96db(A) and a maximum of 110 db(A) at 100 feet forward of the locomotive. The locomotive engineer sounds the horn in advance of a crossing in a sequence of two long blasts, followed by a short blast, then followed by one long blast.

On April 27, 2005, FRA published in the Federal Register provisions of 49 CFR 222, “Use of Locomotive Horns at Highway-Rail Grade Crossings,” which determines when the horn is sounded at public crossings (and at private crossings within “quiet zones”). The Final Rule, which took effect on June 24, 2005, preempts various existing state laws and railroad operating rules and allows for the establishment of quiet zones. A summary of this rule follows on the next page.50

On August 17, 2006, FRA published amendments to the Final Rule in the Federal Register. Effective September 18, 2006, the amendments extended the compliance date of time-based locomotive horn sounding until December 15, 2006. Among the other rule changes were provisions that expanded the time-based requirements to include all locomotive audible devices; provided an exception to the 15-second minimum locomotive horn sounding requirement for trains that re-initiate movement after having stopped in close proximity to a public highway-rail grade crossing; indicated that the time-based criteria for sounding the horn pertains to pedestrian and private crossings in states that require horn sounding at such locations; and clarified that locomotives used in rapid transit are exempt from the locomotive horn sound level requirements.

Additional information, including the full text of the Final Rule, the Final Environmental Impact Statement, and background documents, are available at the FRA Website.51

At the June 2006 meeting of NCUTCD, the council approved for adoption into the next edition of MUTCD language for Part 8, which incorporates those portions of the train horn rule that pertain to traffic control devices consistent with the Final Rule.

Reflectorization. Nearly one-quarter of all highway-rail grade crossing collisions involve motor vehicles running into trains occupying grade crossings. The large size and dark colorization of trains in combination with poor lighting or limited visibility may contribute to motorists having difficulty detecting the train in their path. Reflective material will help reduce the numbers and severity of this type of collision by giving motorists an additional visual warning of the presence of a train.

Reflectorization has become an indispensable tool for enhancing visibility and safety in virtually all modes of transportation. Extending the benefits of reflective materials to railroads will improve highway-rail grade crossing safety and prevent many avoidable collisions.

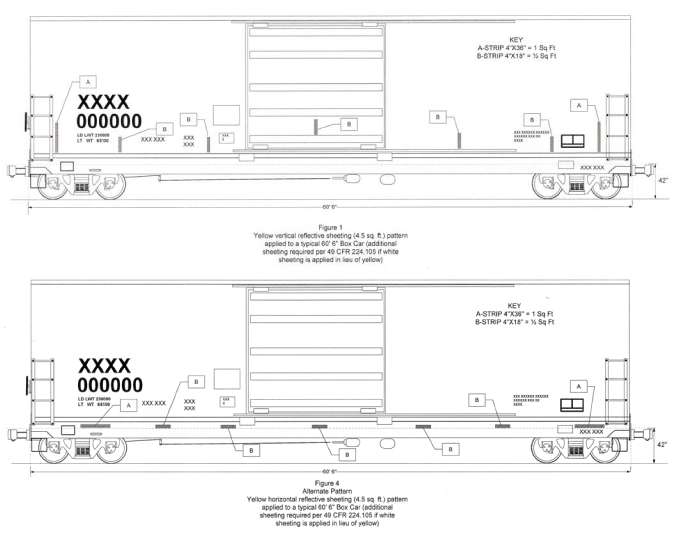

On January 3, 2005, FRA published a Final Rule on reflectorization of freight rolling stock, which took effect on March 4, 2005. Figure 1 shows an example of the reflectorization standards as applied to a boxcar.

FRA issued the Final Rule under 49 CFR 224 to mandate the reflectorization of freight rolling stock, including freight cars and locomotives, to enhance the visibility of trains to reduce the numbers and severity of collisions at highway-rail grade crossings in which train visibility is a contributing factor. The rule establishes a schedule for the application of retroreflective material and prescribes standards for the construction, performance, application, inspection, and maintenance of the material.

The Final Rule on Reflectorization of Rail Freight Rolling Stock requires railroads to install yellow or white reflective materials on locomotives over a five-year timeframe and on freight rail cars over a 10-year period. The reflective materials will be installed on all newly constructed locomotives and freight rail cars and on existing ones during periodic maintenance or repair, unless alternate implementation plans have been developed that meet the requisite timetables. The effective date of the rule is March 4, 2005.

|

Overview The Final Rule on “quiet zones” is intended to:

The public authority responsible for traffic control or law enforcement at the highway-rail grade crossing is the only entity that can designate or apply for quiet zone status. Mandated by law, the Final Rule:1

Local public authorities may designate or request approval of quiet zones in which train horns may not be routinely sounded. The details for establishment of quiet zones differ depending on the type of quiet zone to be created (pre-rule or new) and the type of safety improvements implemented (if required). Once a quiet zone is established (including the continuation of pre-rule quiet zones pending any required improvements), the railroad is barred from routine sounding of the horn at the affected highway-rail grade crossings. FRA provides a Web-based tool for communities to use in performing “what if” calculations and preparing submissions necessary to create or retain quiet zones. The tool may be found on the FRA Website. To ensure proper application of the risk index, the National Highway-Rail Crossing Inventory must be accurate and complete. In the absence of timely filings to the inventory by the states or railroads, local authorities may file updated inventory information, and railroads must cooperate in providing railroad-specific data. FRA regional personnel are available to participate in diagnostic teams evaluating options for quiet zones. Requirement to Sound the Locomotive Horn Outside of quiet zones, railroads must sound the horn 15–20 seconds prior to a train’s arrival at the highway-rail grade crossing but not more than one-quarter-mile in advance of the crossing. Note: Most existing state laws and railroad rules required that the horn be sounded beginning at a point one-quarter-mile in advance of the highway-rail grade crossing and continued until the crossing is occupied by the locomotive. Under the quiet zone rule, for trains running at less than 45 miles per hour, this reduces the time and distance over which the horn is sounded, thereby reducing noise impacts on local communities. The pattern for sounding the horn will remain as it currently exists today (two long, one short, one long repeated or prolonged until the locomotive occupies the highway-rail grade crossing). Train operators may vary this pattern as necessary where highway-rail grade crossings are closely spaced; they will also be empowered (but not required) to sound the horn in the case of an emergency, even in a quiet zone. The rule addresses use of the horn only with respect to highway-rail grade crossings. Railroads remain free to use the horn for other purposes as prescribed in railroad operating rules on file with FRA, and railroads must use the horn as specified in other FRA regulations (in support of roadway worker safety and in the case of malfunctions of highway-rail grade crossing active warning devices). The rule prescribes both a minimum and a maximum volume level for the train horn. The minimum level is retained at 96 dB(A), and the new maximum will be 110 dB(A). This range is intended to permit railroads to address safety needs in their operating territory (this issue is addressed in the preamble text of the Final Rule). The protocol for testing the locomotive horn is altered to place the sound-level meter at a height of 15 feet above the top of the rail rather than the previous 4 feet above the top of the rail. (Cab-mounted and low-mounted horns continue to have the sound-level meter placed 4 feet above the top of the rail.) Note: The effect of this change is to permit center-mounted horns to be “turned down” in some cases. The previous test method was influenced by the “shadow effect” created by the body of the locomotive to indicate a lower sound level than would otherwise be expected several hundred feet in front of the locomotive (where the crossing and approaching motorists are located). The effect of these changes is expected to reduce noise impacts for 3.4 million of the 9.3 million people currently affected by train horn noise. Creation of Quiet Zones The rule provides significant flexibility to communities to create quiet zones, both where there are existing whistle bans and in other communities that heretofore have had no opportunity to do so. The Final Rule permits implementation of quiet zones in low-risk locales without requiring the addition of safety improvements.

The effect of this approach is that horns can remain silenced in more than half of pre-rule quiet zones without significant expense; many new quiet zones can be created without significant expense where flashing lights and gates are already in place at the highway-rail grade crossings. If the risk index for a proposed new quiet zone exceeds the NSRT, supplementary or alternative safety measures must be used to reduce that risk (to fully compensate for the absence of the train horn or to reduce risk below the NSRT). Maintenance of Pre-Rule Quiet Zones Train horns will not sound in existing whistle ban areas if authorities state their intention to maintain pre-rule quiet zones and do whatever is required (see above) within five years of the effective date (June 24, 2005; eight years if the state agency provides at least some assistance to communities in that state). To secure pre-rule quiet zone status, communities must provide proper notification to FRA and other affected parties by June 3, 2005 and file a plan with FRA by June 24, 2008 (if improvements are required). Horns may continue to be silenced at pre-rule quiet zones if:

Creation of New Quiet Zones New quiet zones may be created if all public highway-rail grade crossings are equipped with flashing lights and gates; and either:

Detailed instructions for establishing or requesting recognition of a quiet zone are provided in the regulation. Length of Quiet Zones Generally, a quiet zone must be at least one-half-mile in length and may include one or more highway-rail grade crossings. Pre-rule quiet zones may be retained at the length that existed as of October 9, 1996, even if less than one-half-mile. A pre-rule quiet zone that is greater than one-half-mile may be reduced in length to no less than one-half-mile and retain its pre-rule status. However, if its length is increased from pre-rule length by the addition of highway-rail grade crossings that are not pre-rule quiet zone crossings, pre-rule status will not be retained. Supplementary and Alternative Safety Measures SSMs are engineering improvements that clearly compensate for the absence of the train horn. If employed at every highway-rail grade crossing in the quiet zone, they automatically qualify the quiet zone (subject to reporting requirements). They also may be used to reduce the average risk in the corridor to fully compensate for the lack of a train or to below the NSRT.

ASMs may be applied such that the combination of measures at one or more highway-rail grade crossings reduces the average risk by the required amount across the quiet zone (so-called “corridor approach”).

The rule provides that pre-existing SSMs and pre-existing modified SSMs will be counted toward risk reduction. Recognition of the Automated Wayside Horn The rule authorizes use of the automated wayside horn at any highway-rail grade crossing with flashing lights and gates (inside or outside a quiet zone) as a one-to-one substitute for the train horn. Certain technical requirements apply, consistent with the successful demonstrations of this technology. The Federal Highway Administration (FHWA) has issued an interim approval for the use of wayside horns as traffic control devices. Communities interested in employing this option should contact FHWA to ensure that they comply with the provisions of the interim approval. Special Circumstances A community or railroad that views the provisions of the rule inapplicable to local circumstances may request a waiver from the rule from FRA. A railroad or community seeking a waiver must first consult with the other party and seek agreement on the form of relief. If agreement cannot be achieved, the party may still request the relief by a waiver, provided the FRA associate administrator determines that a joint waiver petition would not be likely to contribute significantly to public safety. FRA grants waivers if in the public interest and consistent with the safety of highway and railroad users of the highway-rail grade crossings. Other Provisions The Final Rule addresses quiet zones that prohibit sounding of horns during the evening and/or nighttime hours. These are referred to as partial quiet zones. The Final Rule requires diagnostic team reviews of pedestrian crossings located within proposed new quiet zones and new partial quiet zones. The Final Rule requires quiet zone communities to retain automatic bells at public highway-rail grade crossings that are subject to pedestrian traffic. The Final Rule extends “recognized state agency” status to state agencies that wish to participate in the quiet zone development process. The Final Rule contains a 60-day comment period on quiet zone applications. The Final Rule requires public authorities to provide notification of their intent to create a new quiet zone. During the 60-day period after the Notice of Intent is mailed, comments may be submitted to the public authority. The Final Rule provides quiet zone risk reduction credit for certain pre-existing SSMs. The Final Rule provides quiet zone risk reduction credit for pre-existing modified SSMs. The Final Rule contains a new category of ASMs that addresses engineering improvements other than modified SSMs. |

Figure 1. Reflectorization Example—Standards Applicable to Boxcars

Source: 49 CFR Part 224, Final Rule, Reflectorization of Rail Freight Rolling Stock, Federal Railroad Administration, Docket Number FRA-1999-6899, Notice No. 6, Washington, DC, October 2005.

Braking. Primarily because of their enormous weight, railroad trains are slow to accelerate and decelerate. Numerous factors affect a train’s acceleration capability, such as the number of locomotive units, the horsepower rating of each unit and, of course, the number and weight of freight cars. At low speeds, a commuter train may accelerate at 1.5 miles per hour (mph) per second; a fast freight may accelerate at 0.3 mph per second. As speed increases, the acceleration rate decreases. A freight with 4.0 horsepower per ton can accelerate at only about 0.1 mph per second at 70 mph.

The braking system used on trains is the air brake that provides adequate uninterrupted pressure from car to car. The single air hose at the end of each car is manually connected to its neighbor, then the brake system is charged. When braking is required, the pressure in the brake pipe leading back through the train is reduced. This causes the valve on each car to use air from the auxiliary reservoir to build pressure in the brake cylinder, thus applying the brakes. For an emergency application, the brake valve opens the brake pipe to atmospheric pressure and the resulting rapid rate of brake pipe pressure reduction causes the car valves to dump the contents of both auxiliary and emergency reservoirs into the brake cylinder.

Braking distances are dependent on many factors that vary for each train, such as the number and horsepower rating of locomotives; number and weight of cars; adhesion of wheels on rails; speed; and grade. Therefore, the braking distance of a train cannot be stated exactly. An estimate is that a typical 100-car freight train traveling at 60 mph would require more than 1 mile to stop in emergency braking.

The majority of crossing collisions involve freight trains, as shown in Table 12.

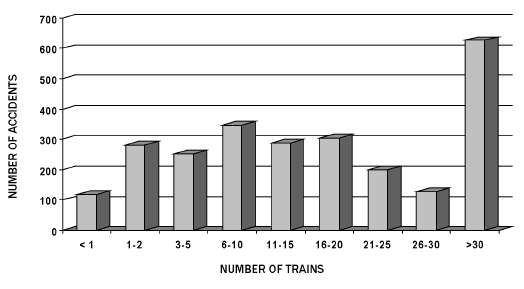

Generally, crossings with higher numbers of trains per day would be expected to have more crossing collisions because the “exposure” (the number of trains per day multiplied by the number of cars per day) is higher for any given highway traffic level. Figure 2 shows the number of collisions in 2004 by the number of trains per day per crossing. Although Figure 2 indicates a dip in the number of collisions for crossings with 21 to 30 trains per day, due to the fact that there are fewer crossings with these activity levels, crossings with higher activity levels have higher collision rates as well.

2. Track

In the United States, railroad trackage is classified into six categories based upon maximum permissible operating speed. FRA’s track safety standards set maximum train speeds for each class of track, as shown in Table 13.

Table 12. Collisions at Public Crossings Involving Motor Vehicles by Type of Train, 2004

Type of train |

Collisions |

Freight |

1,997 |

Passenger/commuter |

227 |

Yard switching |

167 |

Other* |

232 |

Total |

2,623 |

* Note: “Other” includes work trains, light locomotives, single car, cut of cars, maintenance/inspection car, and special maintenance-of-way equipment.

Source: Unpublished data from Federal Railroad Administration.

Number of Accidents/ Number of Trains

Figure 2. Number of Collisions by Number of Trains per Day per Crossing, 2004

Source: Unpublished data from Federal Railroad Administration.

Table 13. Maximum Train Speeds by Class of Track*

Class of track |

Freight |

Passenger |

Class 1 |

10 mph |

15 mph |

Class 2 |

25 mph |

30 mph |

Class 3 |

40 mph |

60 mph |

Class 4 |

60 mph |

80 mph |

Class 5 |

80 mph |

90 mph |

Class 6 |

110 mph |

110 mph |

Class 7 |

125 mph |

125 mph |

Class 8 |

160 mph |

160 mph |

Class 9 |

200 mph |

200 mph |

* Note: If train operations exceed 177 kilometers per hour (110 mph) for a track segment that will include highway-rail grade crossings, FRA’s approval of a complete description of the proposed warning/barrier system to address the protection of highway traffic and high-speed trains must be obtained in advance. All elements of the warning/barrier system must be functioning.

Source: Track Safety Standards Compliance Manual. Washington, DC: Federal Railroad Administration, January 2002.

Initially, there were many different track gauges; however, in 1863, President Lincoln designated 4 feet, 8.5 inches as the gauge for the railroad to be built to the Pacific coast. Other railroads then began changing to this gauge.

The rolling resistance that provides many of the technological advantages for railroads as a means of transportation is made possible by the steel wheel rolling on a steel rail. This steel-wheel-to-steel-rail contact involves pressures of more than 50,000 pounds per square inch, which are then reduced to pressures acceptable to the underlying soil by a series of steps, going from the rail to a steel plate under the rail (tie plate), which spreads the load over a wooden tie, which spreads the load over rock or slag ballast, which spreads the load to a sub-ballast (usually gravel, cinders, or sand), which spreads the load to the subgrade consisting of either the native soil below or some superior material obtained off site.

Rail is rolled from high-quality steel. Rail being rolled today weighs from 115 to 140 pounds per yard and is 6 to 8 inches high. For the last 50 years, the standard rail length has been 39 feet for transportation in 40-foot cars. In track, these rails are held together by bolted joint bars or are welded end to end in long strings. Bolted joints are, however, less rigid than the rest of the rail so that the rail ends wear more rapidly. Continuously welded rail is often used today, particularly on mainline tracks. Rail is welded into lengths of about 1,500 feet and taken to the point of installation. The remaining joints can be eliminated by field welding in place.

The steel rails are spiked to ties typically made of wood with preservative impregnated to prevent decay. The ties hold the rails to gauge, support the rail, distribute the load to the ballast, and provide flexibility to cushion impacts of the wheels on the rail. Prestressed concrete ties have come into greater use on U.S. railroads in recent years but still represent less than 1 percent of the ties in use in the United States

Spikes or other rail fasteners are used to connect the rail to the ties for the primary purpose of preventing the rail from shifting sideways. Because rail has a tendency to move lengthwise, rail anchors are used, particularly on heavy-duty track.

Ballast is used to hold the ties in place, to prevent lateral deflections, and to spread out the load that averages about 100 pound-force per square inch just underneath the tie. Ballast must be able to resist degradation from the effects of tie motion that generate “fines” that may “cement” into an impervious mass. Ballast must also provide good drainage, which is especially important for the strength of the subgrade and also prevents mud from working its way up to contaminate the ballast.

Railway track is normally maintained by sophisticated, high production, mechanized equipment. Track surface is maintained by tamping machines that raise the track and compact the ballast under the ties. In this process, it is often necessary to raise the track a few inches. The best track stability will occur if this raise can continue through the crossing area instead of leaving a dip in the track. Lowering track is a very costly operation and can lead to subgrade instability problems.

Track components are generally replaced as needed. A typical heavy-duty freight line on tangent may be surfaced every two years, have about 25 percent of its ties renewed every eight years, and have its rail changed every 12 years.

Similar to highways, railroad track is classified into several categories dependent on its utilization in terms of traffic flow. Main tracks are used for through train movements between and through stations and terminals. Branch line trackage typically carries freight from its origin to the mainline on which it moves to its destination or to another branch line to its destination. Passing tracks, sometimes called sidings, are used for meeting and passing trains. Side tracks and industrial tracks are used to store cars and to load or unload them.

Table 14. Public At-Grade Crossings by Type of Track, 2005

Other tracks |

Main tracks |

Total |

||||||

0 |

1 |

2 |

3 |

4 |

5 |

> 5 |

||

0 |

9 |

92,421 |

8,642 |

298 |

53 |

3 |

1 |

101,427 |

1 |

13,271 |

17,901 |

1,913 |

60 |

11 |

- |

1 |

33,157 |

2 |

2,756 |

4,997 |

633 |

41 |

12 |

- |

1 |

8,440 |

3 |

761 |

1,325 |

183 |

13 |

13 |

- |

- |

2,295 |

4 |

230 |

425 |

79 |

6 |

6 |

3 |

1 |

750 |

5 |

98 |

161 |

48 |

4 |

- |

1 |

1 |

313 |

> 5 |

78 |

150 |

44 |

1 |

3 |

- |

- |

276 |

Total |

17,203 |

117,380 |

11,542 |

423 |

98 |

7 |

5 |

146,658 |

Source: Unpublished data from Federal Railroad Administration.

FRA reports that, as of 2005, 92,421 public at-grade crossings consist of one main track only. “Main” track is one that carries through movement as opposed to switching movements or terminal movements. Therefore, branch lines have a main track, as do mainlines. Table 14 shows public at-grade crossings by number of main and other tracks.

Collision statistics show that the majority of collisions occur on main tracks. This is, of course, due to the fact that there are more crossings with main tracks and, generally, more train traffic moves over main tracks. Various collision databases (such as FRA, railroads, and local jurisdictions) have varying reporting thresholds and methodologies. Consequently, the specific number of collisions may vary between these databases. Table 15 shows track class and permissible speeds.

3. Signaling

During the early years of railroading, methods had to be devised to ensure that two trains did not meet at the same time on the same section of track. This was initially accomplished through the use of timetables and train orders. Block signal systems were developed, which indicated to the locomotive engineer whether or not a train was ahead in the next block of track. These signals were set manually until the track circuit was developed, which sensed the presence of a train in the block and set the signals automatically. The track circuit was designed to be fail-safe, so that if the battery or any wire connections were to fail or if a rail was broken, a clear signal would not be displayed. Insulated joints were used to define the limits of the block. Various types of track circuits are utilized in automatic traffic control device installations at highway-rail grade crossings. (Refer to discussion in Chapter IV for specifics on train detection.)

Table 15. Track Class and Permissible Speeds

Track class |

Maximum permissible speed |

|

Freight |

Passenger |

|

Excepted |

10 mph (16 km/hr.)* |

Not permitted |

Class 1 |

10 mph (16 km/hr.) |

15 mph (24 km/hr.) |

Class 2 |

25 mph (40 km/hr.) |

30 mph (48 km/hr.) |

Class 3 |

40 mph (64 km/hr.) |

60 mph (96 km/hr.) |

Class 4 |

60 mph (96 km/hr.) |

80 mph (128 km/hr.)** |

Class 5 |

80 mph (128 km/hr.) |

90 mph (144 km/hr.) |

Class 6 |

110 mph (176 km/hr.) |

110 mph (176 km/hr.) |

Class 7 |

125 mph (200 km/hr.) |

125 mph (200 km/hr.) |

Class 8 |

160 mph (256 km/hr.) |

160 mph (256 km/hr.) |

Class 9 |

200 mph (320 km/hr.) |

200 mph (320 km/hr.) |

* No more than five cars loaded with hazardous material are permitted within any single train.

** Amtrak trains are limited to 79 mph (126 km/hr.) unless cab signaling or automatic train stop is provided.

Source: Federal Railroad Administration.

Accident/Incident Bulletin. Washington, DC: Federal Railroad Administration (FRA), published annually.

Armstrong, John H. The Railroad: What It Is, What It Does. Omaha, Nebraska: Simmons-Boardman Publishing Corp., 1982.

Code of Federal Regulations, Title 23, Washington, DC: General Services Administration, published annually.

“Display of Alerting Lights by Locomotives at Public Rail-Highway Crossings.” Termination of Rulemaking, Docket No. RSGC-2, Notice 4. Washington, DC: Federal Register, Vol. 48, No. 88, May 5, 1983.

Poage, J.L., J.C. Pomfret, and J.B. Hopkins. Freight Car Reflectorization. Washington, DC: FRA, Report FRA-RRS83-1, December 1982.

A Policy on Geometric Design of Highway and Streets. Washington, DC: American Association of State Highway and Transportation Officials, 2001.

Post, T.J., G.J. Alexander, and H. Lunenfeld. A User’s Guide to Positive Guidance, Second Edition. Washington, DC: Federal Highway Administration, Report FHWA-TO-81-1, December 1981.

Rail-Highway Crossing Accident/Incident and Inventory Bulletin. Washington, DC: FRA, published annually.

Railroad Facts. Washington, DC: Association of American Railroads, October 1984.

Railroad/Highway Grade Crossing Accidents Involving Trucks Transporting Bulk Hazardous Materials, A Special Study. Washington, DC: National Transportation Safety Board, Report NTSB-HZM-81-2, September 1981.

Bussell, Eugene, R., Beverly Narum, Charles L. Amos, and John M. Schercinger. Compilation of State Laws and Regulations on Matters Affecting Rail-Highway Crossings. Washington, DC: FRA, Report FHWA-TS-83-203, April 1983.

Traffic Control Devices Handbook. Washington, DC: Institute of Transportation Engineers, 2001.

Uniform Vehicle Code and Model Traffic Ordinance. National Committee on Uniform Traffic Laws and Ordinances, Evanston, Illinois, 1961 and Supplement, 1984.

37 Manual on Uniform Traffic Control Devices, 2003 Edition. Washington, DC: Federal Highway Administration (FHWA), 2003.

38 Uniform Vehicle Code and Model Traffic Ordinance. National Committee on Uniform Traffic Laws and Ordinances, Evanston, Illinois, revised 2005 (www.ncutlo.org/modellaws.htm).

39 A Policy on Geometric Design of Highways and Streets, 2004 Edition. Washington, DC: American Association of State Highway and Transportation Officials (AASHTO), 2004.

40 Railroad/Highway Grade Crossing Accidents Involving Trucks Transporting Bulk Hazardous Materials, A Special Study. Washington, DC: National Transportation Safety Board, Report NTSB-HZM-81-2, September 1981.

41 Texas Transportation Institute. “Participant Notebook for a Training Course in Railroad-Highway Grade Crossing Improvement Programs.” Prepared for FHWA, College Station, Texas, revised November 1979.

42 Highway Rail Crossing Accident/Incident and Inventory Bulletin (No. 18 Calendar Year 1995). Washington, DC: U.S. Department of Transportation (U.S. DOT), Federal Railroad Administration (FRA), September 1996.

43 Railroad Safety Statistics 2004 Annual Report. Washington, DC: U.S. DOT, FRA, November 2005.

44 Manual on Uniform Traffic Control Devices, 2003 Edition. Washington, DC: FHWA, 2003.

45 Guidance on Traffic Control Devices at Highway-Rail Grade Crossings. Washington, DC: FHWA, Highway/Rail Grade Crossing Technical Working Group, November 2002.

46 Bureau of Transportation Statistics Website (www.bts.gov).

47 “Compilation of State Laws and Regulations on Matters Affecting Highway-Rail Crossings” (www.fra.dot.gov).

48 “Display of Altering Lights by Locomotives at Public Rail-Highway Crossings: Termination of Rule Making.” Docket No. RSGC-2, Notice 4, Federal Register, Vol. 48, No. 88, Washington, DC, May 5, 1983.

49 U.S. DOT, FRA. 49 CFR Part 229, Railroad Locomotive Safety Standards: Clarifying Amendments; Headlights and Auxiliary Lights; Final Rule.

50 Developed from “The ‘Train Horn’ Final Rule Summary.” Washington, DC: FRA, 2005.

51 U.S. DOT, FRA. 49 CFR Parts 222 and 29 [Docket No. FRA–1999– 6439, Notice No. 16] RIN 2130–AA71, Use of Locomotive Horns at Highway-Rail Grade Crossings.

| Table of Contents | Previous | Next |